Seat, tank and air cleaner out of the way, next was the pipe. Two-stroke motocrossers are so easy!

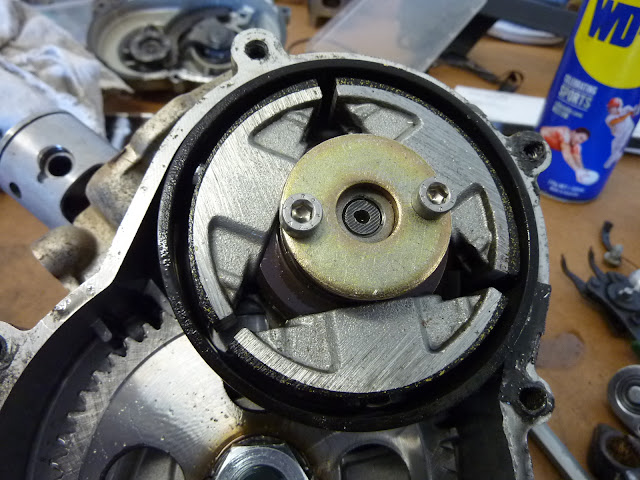

Off with the stator cover to reveal the oil pump drive - previously disconnected on this bike, and a quick feel for play in the crankshaft told me it needed main bearings. Grab the end of the crankshaft and try to pull it up and down, if you can feel play, the bearings are worn. Time to take off the cylinder head and whip out the engine.

The big and small end bearings have a fair amount of play - it's a wonder it sounded as good as it did when it was running. It's a fairly new piston, but I think we might need a new gudgeon pin as well as a connecting rod kit. Oh well, keep going and clutch cover off.

Not much left on the clutch linings - that'll explain the lack of drive. Not much in the way of gearbox either, simplicity itself! Need a puller for the clutch centre. Time for some fabrication.

The perfect washer. Couple of holes, refit the clutch centre-nut and job's a job!

Yes, they've worn very thin - the clutch drum is also worn, but hopefully not beyond spec. The shoes can be shimmed if need be, so let's hope it can be sorted. The new puller can be used on the rotor too - that'll ding dang do for me.

The taper broke with relative ease. This job is going well so far. Time to split the cases.

And there we have the gearbox oil that was being sucked through the seal and mullered bearing!

Time for the blowlamp to warm the cases. Get it to a temperature where your saliva spits back and the bearings should drop out. Gentlemen, spit on your engine (ladies get a cup of water).

Time to whip the piston off. I would have taken it off earlier but the circlips had been put in the wrong place making it harder to get them out. Cheers Pat!

Never mind, with the conrod held in the vice, the piston was soon off. Quick look over, smooth off the rough edges and clean the crown. Sorted.

So we need a crank rebuild, a gudgeon pin, four new bearings (crank and countershaft), three new seals, clutch shoes and a gasket set. Then we start on the chassis.