A nice bit of kit to ride to be fair but, unfortunately for the CBR, was launched over the side of a mountain. Luckily the bushes and undergrowth stopped it plummeting to its death!

Oops was an understatement!

Now we just need to work out how to recover it.

The trusty Ford Falcon. 4 litre, straight six powerhouse (honest).

Keep going, nearly there!

Couple of scratches - should polish out.

Mutant CBR600 - Cool As!

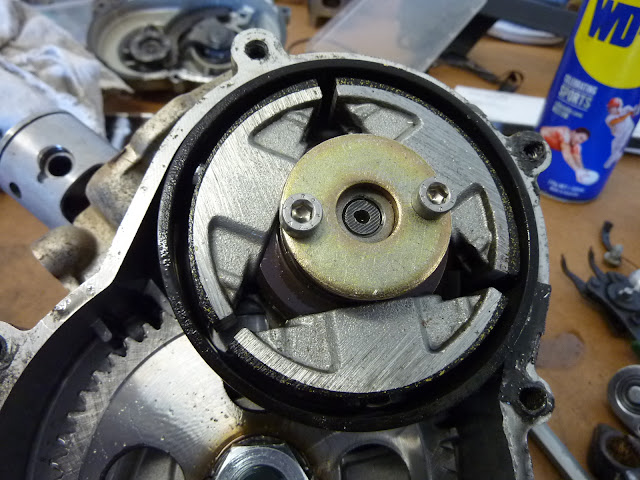

So, once home, it was time to rip off the plastic and check out the important bits. Looks pretty damn good actually. What a cool bike this would be - hmm, a tractor seat is all that's needed to complete her!

A Yoshimura race can