The next thing on the list was the broken fin on the barrels. I cut out a similar shape from some old aluminium that was lying around, then filed it somewhere near. I wanted the barrels to be hot before welding to avoid cracks etc., so a trip to the oven was in order. Half an hour at 150 Celsius was perfect and the liners slid straight out. This was even better because No.4 sat slightly proud before I started.

Roughly shaped, let's take a look.

Not far away, time to break out the TIG.

Bit of corrosion build-up under the liner. Glad I pulled them all out.

It's not pretty, but it's on. Didn't risk going right to the edge of the gasket surface in case it melted. Once filed down, looks pretty good.

With all corrosion cleaned out of the barrels, it was time to reinsert the sleeves. Back into the oven, they all slid back in nicely.

My next issue was the gasket faces. The head was showing signs of corrosion as well as the detonation issues. The barrels were not too bad, but you could just feel the liners sitting slightly proud. Relying on the head gasket to fix those issues is a big ask. I want this engine to be perfect. I dropped the head and barrels off at Paul Gilbert's so he could have a quick look. He confirmed it was detonation, and said he could deck the barrels at the same time. I had them back a couple of days later and they looked amazing!

Getting close to the painting stage. The painting I don't mind, it's the preparation that kills me! It would be nice to get all cases blasted, but that's an expense I just can't stretch to right now. So it's wet & dry, wire brushes, Dremels etc. Engine cases never look perfect unless blasted but, as long as you smooth them out and get rid of the major corrosion, can look pretty good once painted.

Anyway, on to the engine.

I whipped the head and barrels off in the frame, this also makes it easier to lift the engine out.

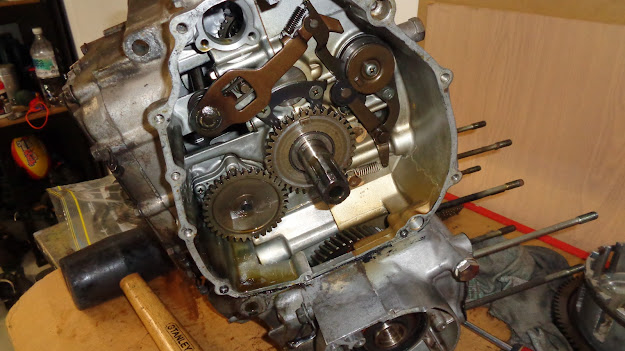

It was nice to see that this engine had never been apart as far as crankcase halves. All screws internally were untouched.

Good to get pictures of where the cable clamps were.

The screw holding the selector shaft in was tight! Unfortunately I mullered the head of that one getting it out. It'll get replaced.Everything so far looks excellent.

The oil pickup screen has a fair amount of debris in it, mostly fragments of chain guide by the look of it.

The crank, and the most important bit. Doesn't appear to be any abnormal play or wear anywhere, happy days.

Gear clusters look good too.

Numbered, just in case.

That's the engine stripped. Here's a pic of the original cylinder head and its burnt out valve.

There was a lot of carbon build-up in fairness. That valve didn't even move freely in its guide until the engine was warm. My bad, should have decoked it long ago.

More soon, time for the clean up and painting of cases.

No comments:

Post a Comment