Cutting out and doing my head in...

The R1 is getting plenty of use lately, but has one major niggle - it often refuses to idle at junctions which, in turn, makes it extremely hard to pull away from standstill. Even if you hold it at around 2,000RPM, it tries to cut out as you pull away. Once out on the road, it seems pretty good, but the inability to blip properly going down through the gears is becoming a pain.

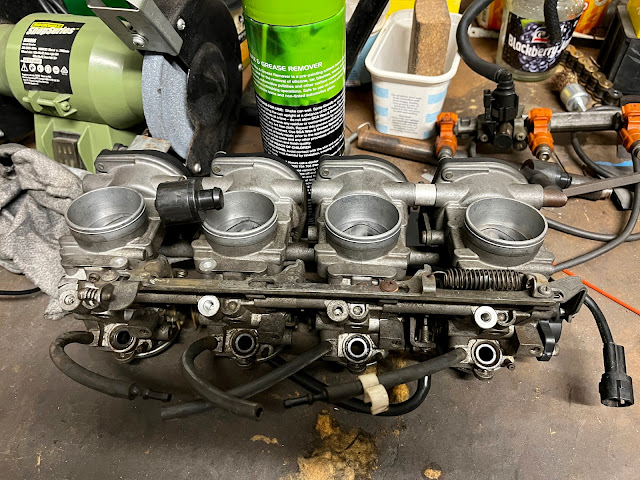

I was going to wait until I drop the engine out for a valve clearance check, and replace some gearbox bearings, but the other night I was feeling motivated so I thought I'd rip off the throttle bodies for a look over and clean. So, with tank and airbox removed, I unscrewed the cold start plunger and set about taking the fuel rail and injectors out. Once these are out of the way, you can see the clamps holding the throttle bodies.

The TPS and air pressure sensors were unplugged and throttle cables disconnected when I lifted up the throttle bodies. A quick look at the inlet rubbers and they seemed to all be ok and fitted correctly. I also took the opportunity to spray carb clean onto the inlet valves (when closed) to see if they were sealing correctly, they are all perfect.

Next, it was onto the throttle bodies and start the cleanup. The outsides were done first with a toothbrush and carb clean. Then the air screws were taken out. Make sure you retrieve the spring, washer and o-ring from within the hole so they don't get lost during the cleanup. The four vacuum hoses you can see are for balancing/synchronising the throttle bodies.

They are a little bit corroded, but are a damned sight better than when we started. One day it'll get the allover treatment, for now we want them to work correctly and be spotless where it counts.

I also removed the TPS so it didn't get damaged, and gave it a clean/check of the wiring etc.

Next came the diaphragm caps and slides. This is where I found major dirt buildup, and one of the major issues. The diaphragms were coated in red silt and this abrasive was also rubbing on the slides. The tops, slides and diaphragms were all taken to the sink where they were cleaned up with water and Jif. Be very careful with the diaphragms as they can be a bit fragile. The difference afterwards was huge, the rubber felt soft again. A small screw at the bottom of the throttle bodies can be removed allowing the alloy guide to be dropped out and cleaned - the dirt was also down inside where this is fitted. Removal was the only surefire way of cleaning it. There is an O-ring on this too so I cleaned it all up and refitted it with Vaseline to make sure it slid into place ok.

All airways were washed through with carb clean and then blown out with compressed air. Once I was sure everything was clean I rebuilt the bodies. The manual says not to adjust, or synchronise, the butterflies with the adjusting screws, but two of mine were slightly out. I took a thin piece of stainless steel (see photo below) and inserted it under the butterfly of number three, and adjusted the idle screw so that it was a nice sliding fit. Once I was happy with the "fit" I tried it in the other three. Two needed an adjustment.

The air screws were reassembled with spring fitted, then the washer and finally the O-ring. These were screwed in until they gently bottomed out, and backed off 3/4 of a turn each. The TPS was refitted but the screws left loose for now.

Once inlet rubbers were all cleaned and ready, I smeared a little Vaseline around them to help the throttle bodies back in. Before they are pushed home, a voltage check is required on the TPS. The manual states that you need 0.63v - 0.73v at closed throttle, measured at the blue and yellow wires. This is actually incorrect and you need to measure at the yellow and black wires. Move the TPS to get the correct voltage and tighten up the two tamperproof Torx screws. Now the bodies can be refitted.

I took the injectors out of the fuel rail so I could give them a quick clean and blow out the rail itself. These were refitted after cleaning and greasing the seals. Then the rail and injectors were refitted. Once the vacuum lines were back on, I connected my Morgan Carbtune to the relevant vacuum hoses. Then I loosely fitted the airbox, and refitted the tank with a piece of wood to hold it up at an angle. I was now able to start the bike and warm it up.

Once warm I set the idle to 1,100 RPM and started to synchronise the bodies. I soon had them pretty close. In fact, they were pretty good from the start. After several checks, it appeared I wasn't going to get them any more accurate so it was off with the carb balancer, and reconnect the blanking plugs into the test hoses. The airbox was fitted correctly, and tank etc. put back.

Note regarding diagnostics.

I also decided to test the resistance of the air temp sensor in the airbox while it was off. The manual states that it should be 450-550 ohms at 20°C. Mine was 2700 ohms — it did move when my fingers were on it showing that it was registering a change in temperature but, going by the manual, it must be knackered. I was about to order another when I found a post on the R1 forum stating that the manual is wrong regarding the TPS measurement (Yamaha had brought out a bulletin to rectify the fault), and also that when the guy bought a brand new air temperature sensor from Yamaha, it was also reading way out of spec.

I guess what I'm saying is, don't take the manual as gospel. There were no fault codes in the ECU regarding these components, yet you would assume they were faulty. Question these things before chucking parts at it.

Verdict.

The difference in this bike is absolutely incredible! It idles perfectly, and is now smooth from low throttle through to any position making it far easier to ride, and nicely brutal in first gear.

Having read several forum posts regarding poor idle of the 2002 - 2003 R1, I thought it might be a typical fault, but now I can see that the first of the injected models can run as well as anything else. It's now the bike I actually wanted, a quick, capable street-fighter derived from an actual sports bike.

Happy!

No comments:

Post a Comment